Wire arc spray

CabCoat – Wire Arc Spray is a form of thermal spraying used for wear resistance, corrosion protection, dimensional restoration, bond coat on large components or for the building up of worn components.

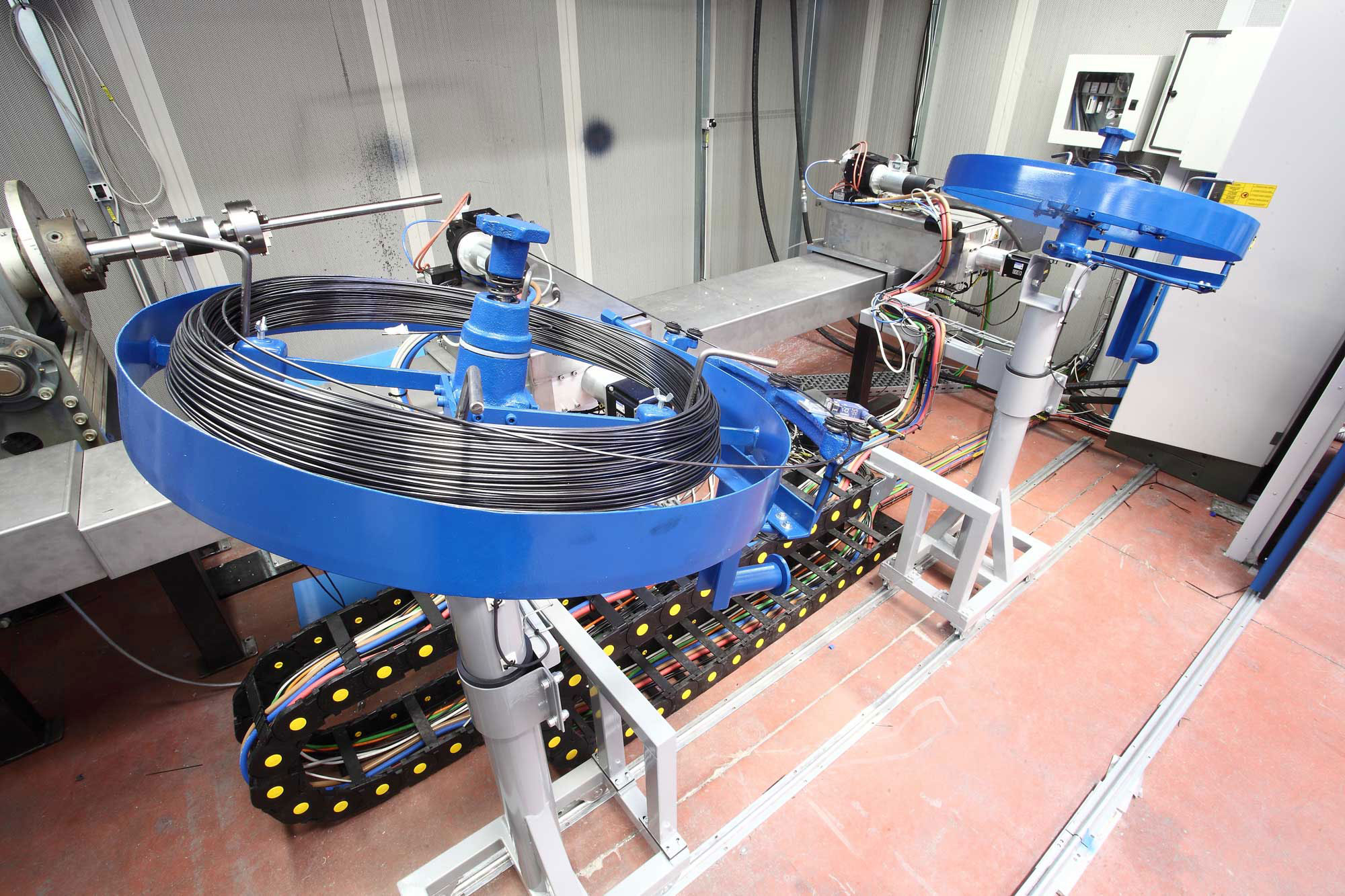

CabCoat Coating equipment is set up as individual production units or as an integrated part of a complete manufacturing line.

Lincotek Equipment has developed specific solutions for the integration of Spray Core items with specially designed and state-of-the-art handling and peripheral components, giving you the overall coating process you are looking for.

Typical coating equipment consists of core items, handling elements and peripheral components.

Lincotek Equipment offers everything from core items up to peripheral components in one customized package, or as stand-alone components integrated into existing coating equipment.

| SPRAY CORE | HANDLING | PERIPHERAL |

|---|---|---|

| Controller System | Robot | Booth |

| Gun | Lathe | Ventilation |

| Powder Feeder | Tilting | Filter Systems |

| Power Supply | Carousel | |

| JAM Box |

Main benefits

- Wide range of applications

- Built on experience

- Double door with carousel

- Full closed loop control of all coating parameters including mass flow control of the process gases (and fuels) and carrier gases.

- Option of an L-door for better access and safer working conditions for operators

- Power distribution unit to power up all peripherals

- Ease of operation and maintenance

- Everything under control: full integration with heat exchangers, part handling (robot/turn-table/lathe) and exhaust filter systems (power and data exchange)

- Touchscreen operator interface with intuitive visualization software

- Remote maintenance capability

- Sophisticated tracking and recording package

- Real time monitoring

- Multilevel alarm system and multilevel access

- Storage process recipes

- Soundproof booth to guarantee standard acoustic emission < 78Db