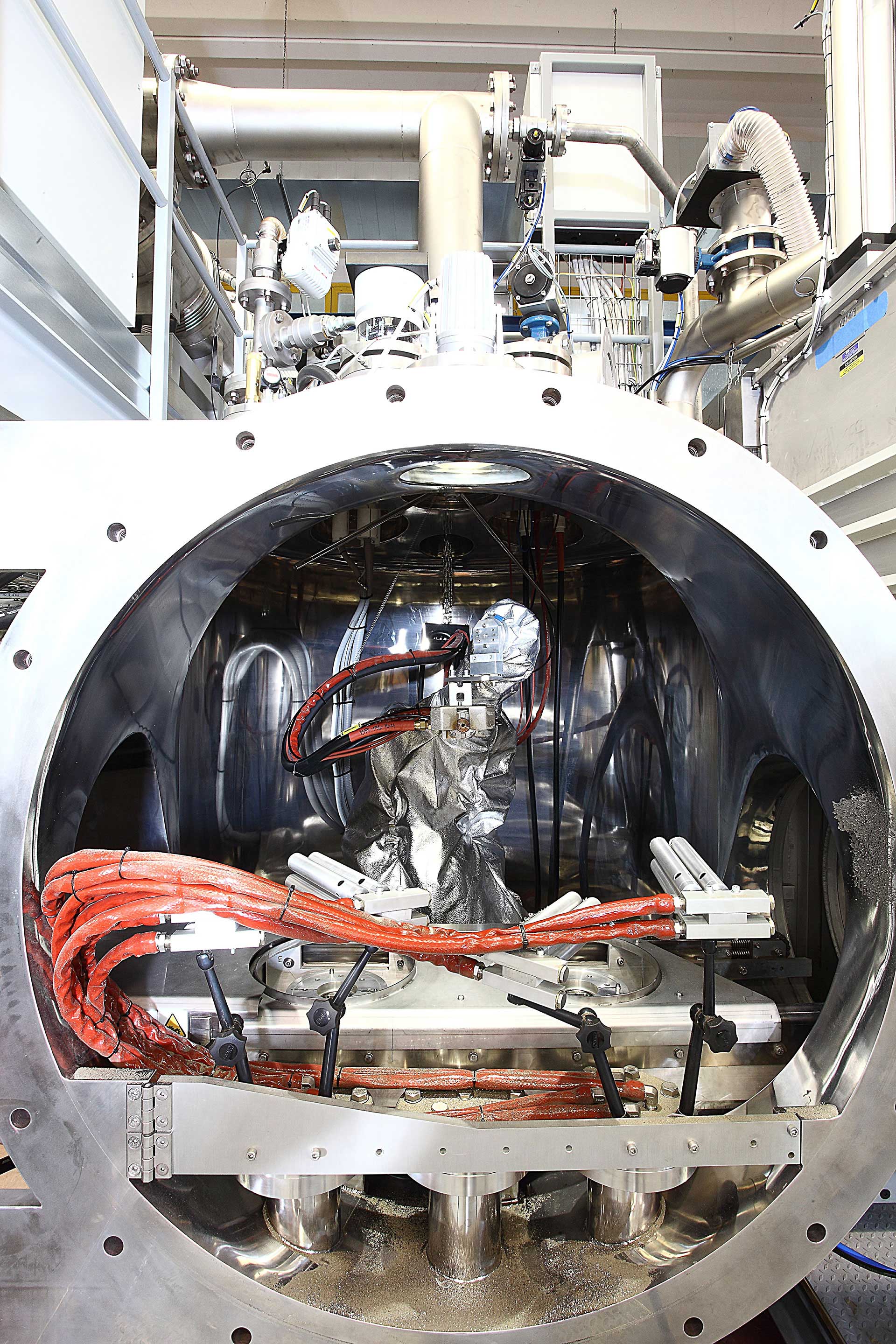

Controlled Atmosphere Plasma System (CAPS)

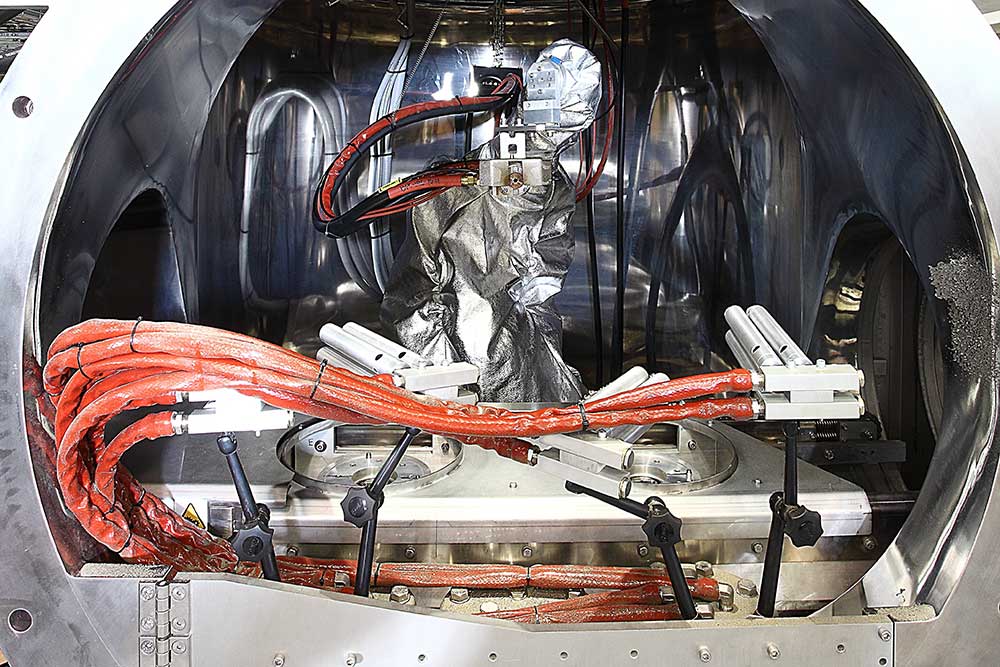

ShellCoat – CAPS is designed for high-end applications in plasma spray for coating that is thin, dense, oxide-free, and very pure. The purpose of NEW CAPS equipment is to perform plasma coating in a controlled (air, argon and nitrogen) atmosphere, reducing the amount of oxide in the coating. The main chamber is used to apply plasma coating to different applications – such as land-based and in-flight turbine components and biomedical parts – as well as solid oxide fuel cells and combustion chambers.

Its design allows a complete evacuation of the oxygen through a vacuum, after which the chamber is backfilled with inert gas (Argon) to reach the level of pressure appropriate for the plasma spray recipe. The NEW CAPS equipment has a conveyor on a rail system that uploads/downloads parts from the transfer chamber (Pre-Chamber) to the coating chamber (Main Chamber). The Main Chamber and Pre-Chamber are separated by a gate valve, which allows the conditions inside the main chamber to be fully preserved.

The NEW CAPS equipment incorporates Lincotek Equipment’s control plasma-coating system to give you full control and a user-friendly interface. All components and parts are designed to work in a hot and dusty coating chamber environment.

Shell Coating equipment is set up as individual production units or as an integrated part of a complete manufacturing line. Lincotek Equipment has developed specific solutions for the integration of Spray Core items with specially designed and state-of-the-art handling and peripheral components, giving you the overall coating process you are looking for. Typical Shell Coat equipment consists of core items, handling elements and peripheral components. Lincotek Equipment offers everything from core items up to peripheral components in one customized package or as a stand-alone component integrated into existing coating equipment.

| SPRAY CORE | HANDLING | PERIPHERAL |

|---|---|---|

| Control System | Robot | |

| Gun | Multi-Spindle | Ventilation and Filter Systems |

| Powder Feeder | Loading & Unloading Conveyor | Vacuum Pumps |

| Power Supply | Carousel | Vacuum Chamber |

| JAM Box | Sting | Pre-Chamber |

Main benefits

- Built on experience

- Wide range of materials (Metal alloys, carbides, blends, cermets, abradable and oxide ceramics)

- Full closed-loop control of all coating parameters, including mass flow control of the process gases (and fuels) and carrier gases.

- Power distribution unit to power up all peripherals

- Ease of operation and maintenance

- Argon, hydrogen, nitrogen and/or helium plasma gases

- Wide range of applications

- Compatible with all types of powder feeders

- Everything under control: full integration with heat exchangers, part handling (robot/turn-table/lathe) and exhaust filter systems (power and data exchange)

- Double walled chamber (cooling system)

- Touchscreen operator interface with intuitive visualization software

- Remote maintenance capability

- Sophisticated trending and reporting package

- Real-time monitoring

- Multilevel alarm system and multilevel access

- Storage process recipes

- The loading/unloading of workpieces via a completely automated one-in/one-out automated system

- All vacuum connections, transfer chambers, filters and vacuum pumps are made of stainless steel AISI 316L pipes.